While there are various fall protection options available, the focus of this post is the use of Guardrail Systems.

Guardrails are so common they’re frequently taken for granted, but when they are absent, their significance is glaring. To help give workers the appropriate safety precautions while on site, it’s essential to make sure guardrails are correctly installed and working. Every. Single. Time.

This is often the reason guardrail systems fall short of expectations: the system itself was improperly installed on site and as a result, is hazardous to worker safety. Inadequate guardrails will provide workers with a false sense of security, which can result in injuries and costly OSHA fines.

Fortunately, the OSHA guardrail requirements are clear and simple to adhere to. There’s no excuse to cut corners when it comes to worker safety. It’s worthwhile to go that extra mile to comply with OSHA standards and protect your team.

Leading Edges and Guardrail Systems

What does the phrase “leading edge” in construction safety actually mean? OSHA defines a leading edge as the edge of a surface from which employees might accidentally fall. This is typically thought of as falls from elevated heights like commercial roofs, building framework, and/or scaffolding. However, it includes ground-level dangers like open manholes, trenches, wells, and any other kind of ground hole.

*It’s crucial to know that ground-level leading edges could be subject to separate laws, such as manhole-restricted space access rules.

The magic number when dealing with fall protection systems is 6’ (six feet). Whenever there is a drop of six feet or more from the leading edge, a fall protection system must be in place. No questions asked. Six feet may not seem that high, but if a worker falls from that height, their risk of serious injury increases drastically. According to OSHA standards, a guardrail system is required in the following situations:

- Elevated work areas: Guardrails are required for open sides of elevated work areas that are 4 feet or higher from the adjacent floor or grade.

- Stairways: Guardrails are required on both sides of stairways that are 30 inches or more above the adjacent floor or grade.

- Roofs: Guardrails are required for roofs with a pitch greater than 4 in 12 and for low-slope roofs that are not completely surrounded by walls or screens.

- Ramps: Guardrails are required on ramps that are 30 inches or more above the adjacent floor or grade.

*It is important to note that these are general guidelines and employers should refer to OSHA standards for specific requirements and details on guardrail systems in the construction industry.

OSHA Standards for Guardrail Systems

The standards set by OSHA for how guardrails should be designed, installed, and maintained to protect workers from falls, injuries, and hazards are vital to follow. These standards cover everything from the height and strength of guardrails to the placement of mid-rails and toe boards.

These standards set by OSHA are all about keeping workers safe and sound on the job site! Adapting these standards as your own is a must for any employer who wants to create a happy, healthy, and safe work environment for their employees. So, let’s all work together to make sure everyone is protected!

Per OSHA standards, all guardrail systems installed on-site must adhere to the following requirements:

- Height Must be between 39-45 inches above the walking-working surface.

- The top rail must be smooth, able to withstand a force of 200 pounds in any direction, and installed at a height of 42-46 inches above the walking-working surface with 42 inches being the ideal height.

- The mid rail must be installed halfway between the top rail and the walking-working surface, typically at 21 inches, and must be able to withstand a force of 150 pounds without failing and not have any opening greater than 19 inches. OSHA does allow alternatives such as mesh and balusters but they must also meet the same weight requirements.

- Bottom rail aka “toe boards” must be at least 3.5 inches high, securely fastened in place, and have no more than 1 inch of clearance between the bottom edge of the toe board and the walking-working surface, and it’s required to extend the entire length of the guardrail.

- Load rating: All guardrail systems must have a minimum load rating of 200 pounds.

- Unique situations: If workers are using stilts, the guardrail system may need to be taller than 45 inches to safely protect them. In this case, the heights of the stilts’ and guardrail system must coincide… Meaning if the worker is wearing 30-inch stilts, then the installed guardrail system must be 72 inches tall (42 inches + 30 inches), to safely protect the worker

Build an OSHA-Approved Guardrail System

There are times when a job site-built guardrail system is a perfect solution for the current situation. As long as all OSHA requirements are followed when constructing that guardrail system, there’s nothing wrong with using them. Just remember to adhere to their strict requirements so you can ensure all your employees’ safety.

- Wood: OSHA advises using construction-grade 2×4 lumber with a minimum stress grade of 1500 lb-ft/in² for the posts and top railing and 1×6 lumber for the mid-rail when building a traditional guardrail system with a mid-rail. Additionally, the distance between the posts shouldn’t be greater than 8 feet.

- Steel: OSHA advises using structural steel angles that are a minimum of two inches by two inches by 3/8’’ (three-eighths inch) or schedule 40 pipes that are at least 1½’’ (one and a half inches) in diameter for those who want to weld a metal railing system, with no more than 8 feet between posts for either option.

Although the hardware needed to secure the guardrails to the ground is not specified in the OSHA guidelines, the Safety Boot guardrail system is a practical workaround. This bracket system, when combined with the suggested building materials & securely fastened to the substrate, can help guarantee that your guardrails comply with OSHA requirements.

*Please be aware that even though OSHA suggests using these materials for construction, you are free to use other materials as long as they meet OSHA’s requirements for height, coverage, and weight.

Available Guardrail Systems

(Temp, Parapets, & Ground-Level)

What if the job site you’re on requires a guardrail system but you’re worried about the time, labor, and costs required to build a system safe enough for your workers and/or the potential effects it might have on the substrates of the work site? There are companies that offer various temporary guardrail systems specifically designed to cut costs, reduce the number of man-hours required to install, and still meet all of OSHA’s guardrail requirements.

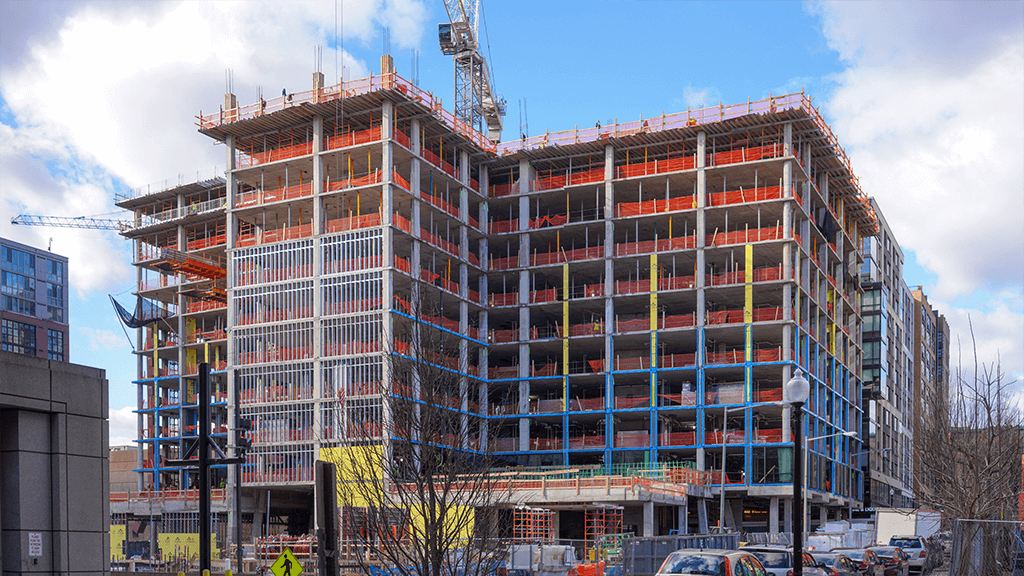

If your job sites are like ours—large-scale commercial projects with multiple stories that all have long-running leading edges—then we have a great guardrail system to recommend. The Grainger stand-alone temporary guardrail system or something similar is designed to significantly reduce installation time without sacrificing worker safety. Two workers can quickly erect 170ft of this system in under an hour. Additionally, the option to add toe rails and/or gates makes these systems customizable and able to protect workers from any hazardous situation.

On our projects that have parapets, you will typically find the standard OSHA-approved “Clamp” guardrail systems. These are a great option because of the simplicity of their enormous clamps that can be fastened to the parapet quickly and securely without requiring any drilling or modifications to the structure and still provide complete protection.

When it’s required to protect not just employees but pedestrians and/or moving vehicles from potential hazards like an exposed manhole, OSHA calls for a ground-level guardrail system to be installed. These systems have their own added advantages compared to systems used at heights which consist of better visibility, increased safety, and even lower maintenance costs. With the number of guardrail systems available for everyone’s specific needs and budget, there’s no excuse to not have them on site.

Other Available Options (OAO)

Guardrail systems are typically the first option chosen to protect workers while working on or around leading edges, but they’re not the only option. If a situation calls for the installation of guardrails but it’s either impossible or impractical, the use of alternative options like safety nets are an approved fall prevention measure according to OSHA. It’s important to remember that similar to guardrails, safety nets also have very strict and detailed requirements that must be met when they’re in use.

Other options found on job sites are fall-resistant systems like SRD and lanyards. These types of fall protection are for use in situations where there is a leading edge but it’s not possible to erect any type of guardrail system to safely protect workers. Typically these three-part systems involve the worker donning a full body harness, attaching it to an arresting device like an SRD or lanyard, and clipping it to an anchorage point that can support up to 5,000 pounds.

Learn How to Properly Don a Full Body Safety Harness

Don’t Take Short-Cuts

Accidents on job sites can be expensive for both the worker involved and the company. They’re typically easily avoidable if the proper safety precautions are set in place and followed. Just like Robey Inc., the most successful construction companies make job site safety a top priority for all their employees across all projects. We believe it’s about more than just following OSHA regulations. It’s about implementing safety standards and risk management practices into our employees’ daily routines, ensuring that it becomes a natural part of our company’s culture.

Go that extra mile and take advantage of the many tools available to help keep all workers on site safely working and able to go home at the end of the day.

Fact: Falls from height account for nearly 40% of all fatalities in the construction sector, and the reason why OSHA cites MILLIONS OF DOLLARS in fines for height-related hazards on job sites all across America every year. Make safety a priority on the job site.

*Disclaimer* Any tools and/or safety systems including but not limited to guardrail systems discussed in this blog posting should only be used by skilled professionals who have received training on how to use the tools and/or systems described on this page and are aware of the risks associated with their line of work. Robey Inc. disclaims all liability for mistakes or omissions made in the use or abuse of any purchased product(s). The use of this information or the contents of this page does not in any way subject Robey Inc. to liability for any direct, indirect, consequential, incidental, special, or other damages of any kind, whether in a contract dispute, negligence claim, or other tort claims. At any time now or in the future Robey Inc. reserves the right to add, remove, or change anything written in the blog post.